Benefits for Bond Experts

AdheScan provides reproducible, quantifiable results for common adhesive failure patterns. It utilizes two line scan cameras by Schäfter+Kirchhoff (type SK4k-U3DR7C, color, pixel size 7 µm) and provides a high-resolution image (11 µm optical resolution) of both surfaces of the fracture pairs. The cameras are used in a stereo configuration to provide additional valuable height information with a resolution of 20 µm. Combining the images with the height information, a 3D representation of the sample is generated. The standard system scans up to 8 adhesive failure pairs (8 pairs of substrate and stamp) less than 45 seconds and calculates the height information in approximately 20 seconds. It also shows a typical sample holder with 8 fracture pairs. It is also possible to scan different types of samples with the help of a specially adapted sample holder. The high-resolution image and the height information are the basis for the subsequent evaluation using a machine learning algorithm. The software allows the user to easily train the machine learning algorithm to automatically evaluate samples in seconds. A well-trained algorithm has a processing time of only about 4 seconds for the evaluation of 1 pair of samples, depending on the computer hardware. Adhescan is a further development of a demonstrator, that was developed in cooperation with Fraunhofer IFAM (Department of Adhesion and Interface Research & Quality Assurance and Cyber-Physical Systems) in a project (SAMBA, 20Q1924A) publicly funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK). The customization for this particular application and the implementation of the machine learning algorithm were made possible through close collaboration and knowledge sharing. The patent is pending (not yet published)

Software SKan-AD: Surface Failure Inspection using the AdheScan

The normal procedure for evaluating a set of samples with AdheScan includes several routines inspired by practical experience, e.g. a previously defined ROI set and the input of meta information such as the adhesive used and the substrate materials

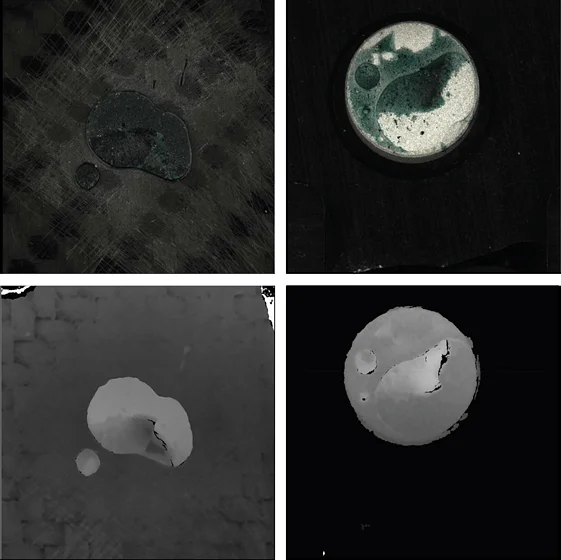

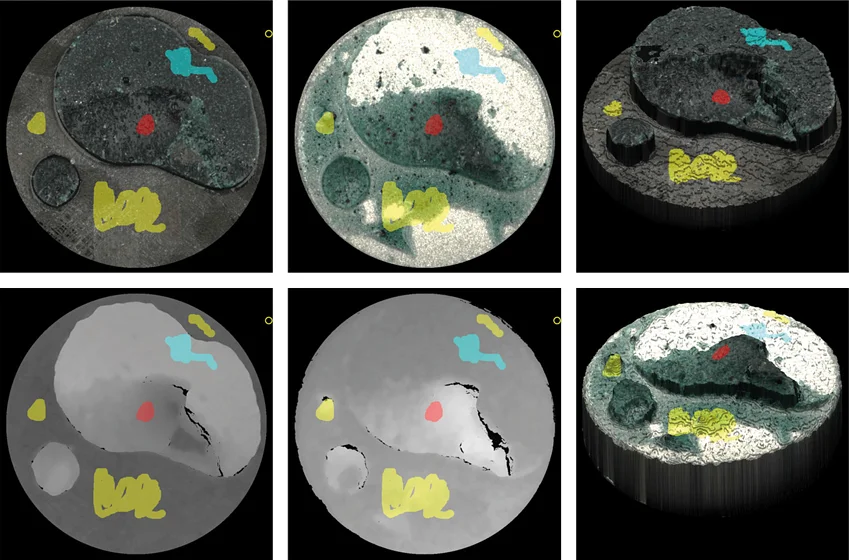

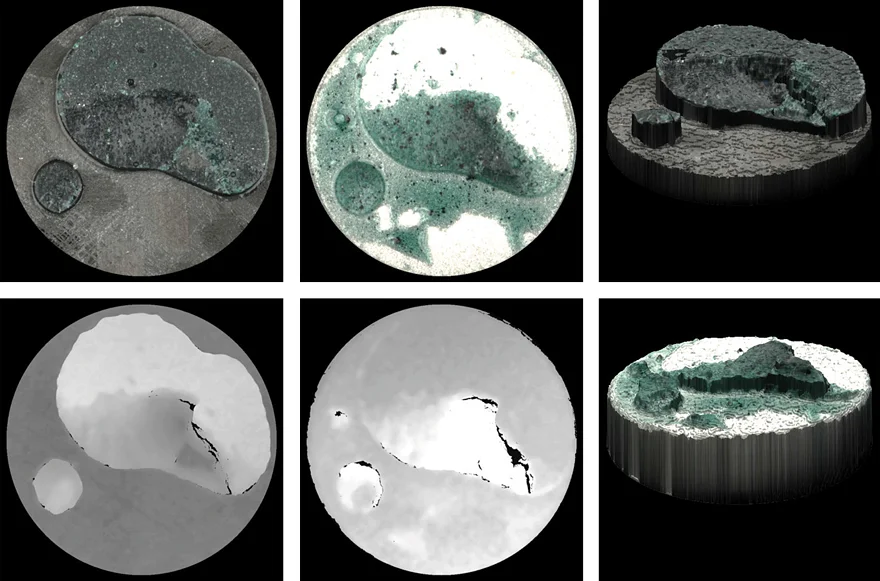

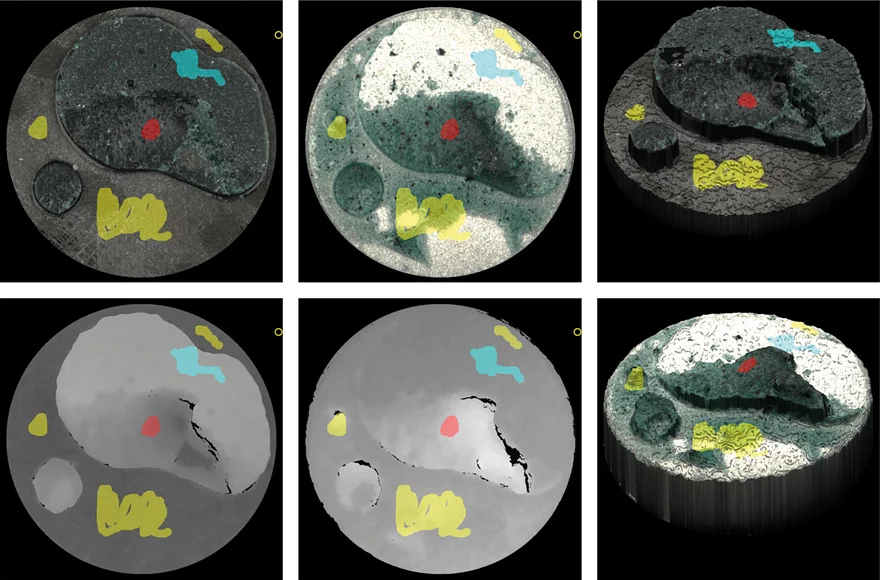

1. Image acquisition: 2x2 view with the two high-resolution images of the two fracture pairs and the corresponding display of the height information.

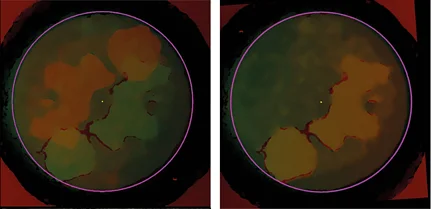

2. Comprehensive view: Overlay visualization for the alignment of both fracture partners - before and after alignment. Enhanced accuracy because all 4 images (high-resolution and height image) must be considered and evaluated together.

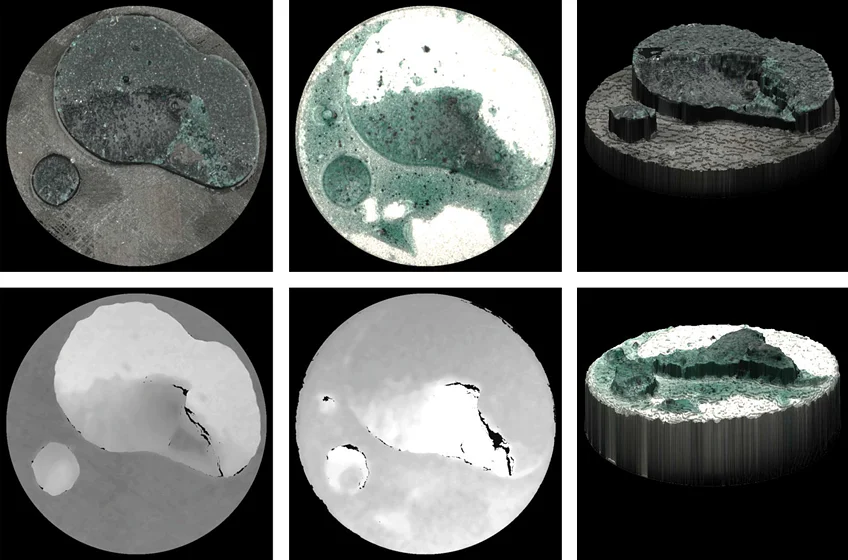

3. 3D image: High-resolution images of both substrate and the stamp , height information for both substrate and stamp as well as the corresponding rotatable 3D images of both substrate and stamp.

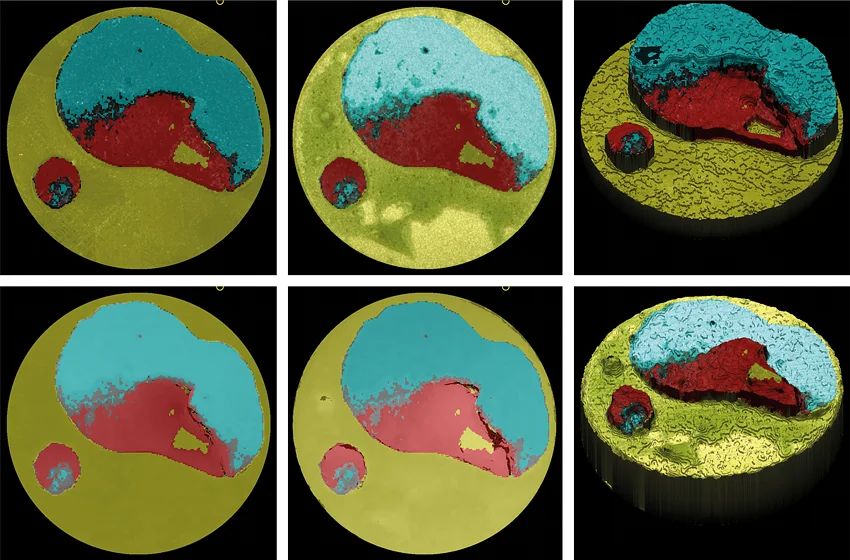

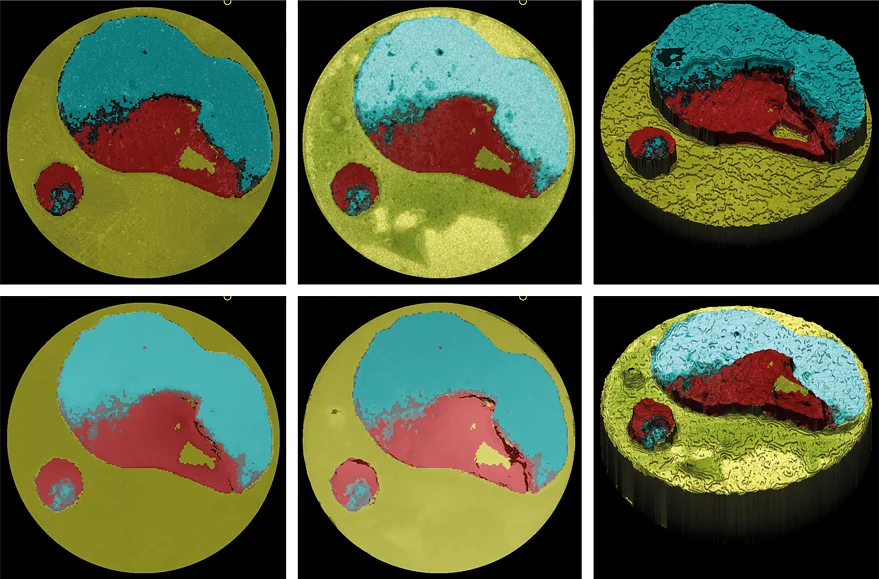

4. Annotating assistant with pair of assignment: The user marks the fracture classes where the fracture pattern is easiest to identify in either the high-resolution or height image. All other images are marked live for more accurate results.

5. Quantifiable results: Even with only a few markers, the implemented algorithm can make a prediction for the entire image. The complete image is now divided into the corresponding fracture patterns according to the predefined labels, e.g. 25% CF, 35% AF and 40% customized failure type.

Transferring expert knowledge to the machine-learning algorithm

The annotated images can then be selected as a sample set to be used for teaching the algorithm. Once the data set is selected, the training process of the algorithm can be started. For verification, a portion of the training set is evaluated with the trained algorithm and compared to the manually evaluated results. If the result is good, the process of training the algorithm can be completed by releasing the algorithm. The resulting „skilled“ algorithm can now be selected in process mode to use the machine-learning-assisted fracture inspection.

Quality of the results

The software provides several in-depth features (such as histograms, heat maps, etc.) to evaluate the quality of the result. A threshold value can be defined. This determines whether the analyzed sample is considered a reject. All results are logged and all relevant data is stored in a database for easy retrieval of previous results.

Modes of evaluation

The system scans up to 8 adhesive failure sample pairs in less than 45 seconds and calculates the height information in approximately 20 seconds. Depending on how well the features of both sides are visible in relation to each other, aligning the samples can take anywhere from 30 seconds to 2 minutes.

1. Manual evaluation: When evaluating samples manually, the time may vary from user to user, depending on the desired accuracy and the number and identifiability of fracture patterns. In general, the evaluation can take between one and five minutes.

2. Process mode: In process mode, the trained algorithm takes over the evaluation of the images, after the user has aligned them properly. For a typical image size of 900x900 pixels, the algorithm needs about 4 seconds to evaluate the sample. However, this depends on both the image size and the processor performance. A large number of samples, e.g. in-process samples, can now be evaluated in an efficient, reproducible, and accurate manner.

3. Prediction mode: The prediction mode was developed for laboratory applications when dealing with very frequently changing substrate/adhesive samples.