Features

The AdheScan is an advanced, user-friendly comprehensive measurement system for the quantifiable, reliable and reproducible inspection of adhesive failure surface patterns. The system is designed to utilize expert knowledge in an objective and reproducible way. Bond Experts profit from ease of use as well as specially designed image acquisition in combination with trainable machine-learning algorithms (included in SKan-AD software)

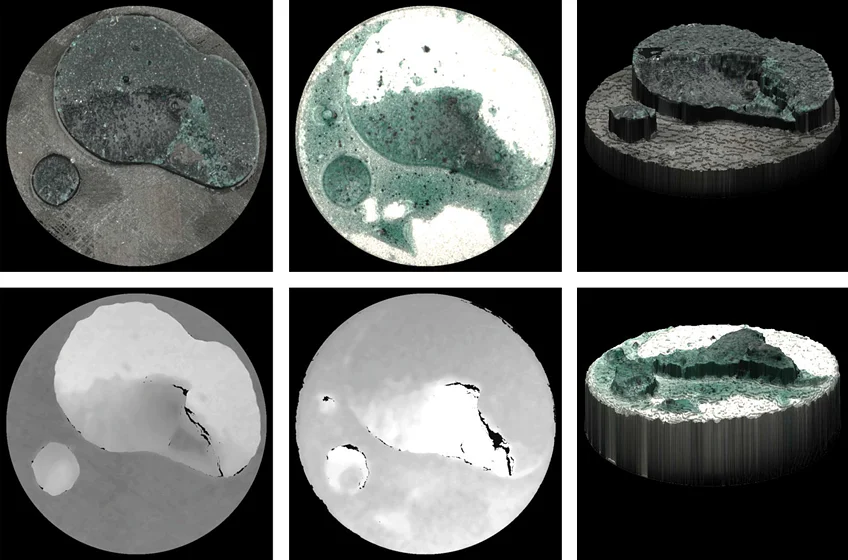

Ease of use: Intuitive routines, high resolution, 3D height information and 3D view of each fracture pair; scans of up to 8 fracture pairs in one scan

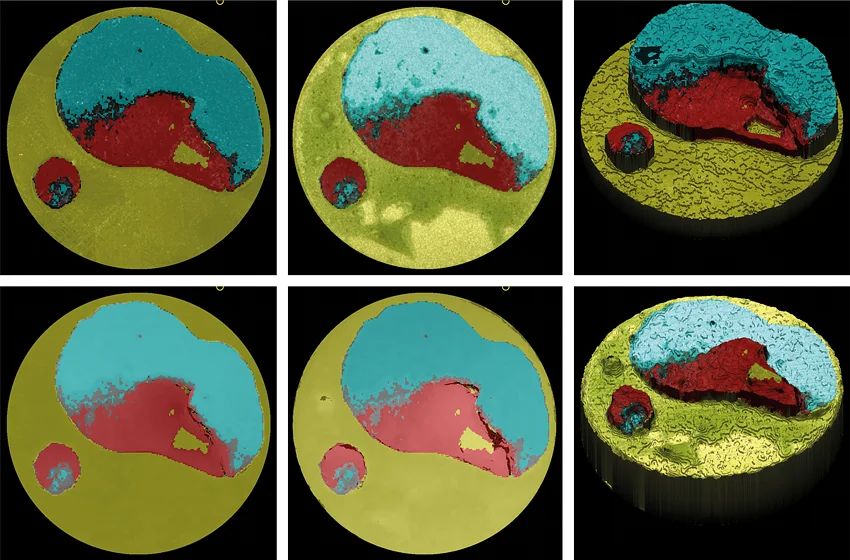

Quantifiable results: Quantifiable, reproducible results for adhesive fracture surface patterns. All results are logged and all relevant data is stored in a database for easy retrieval of previous results

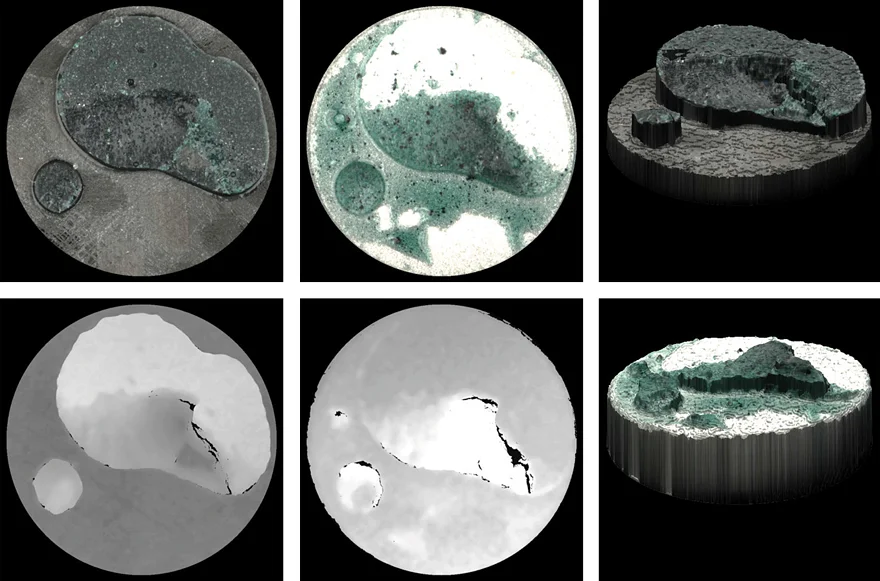

Comprehensive view: Both fracture partners are aligned using the alignment tool and then evaluated together for increased accuracy

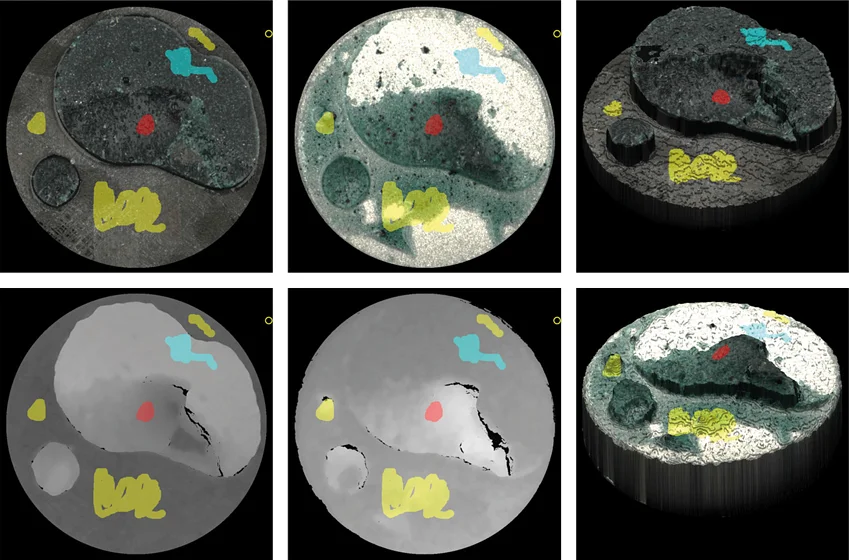

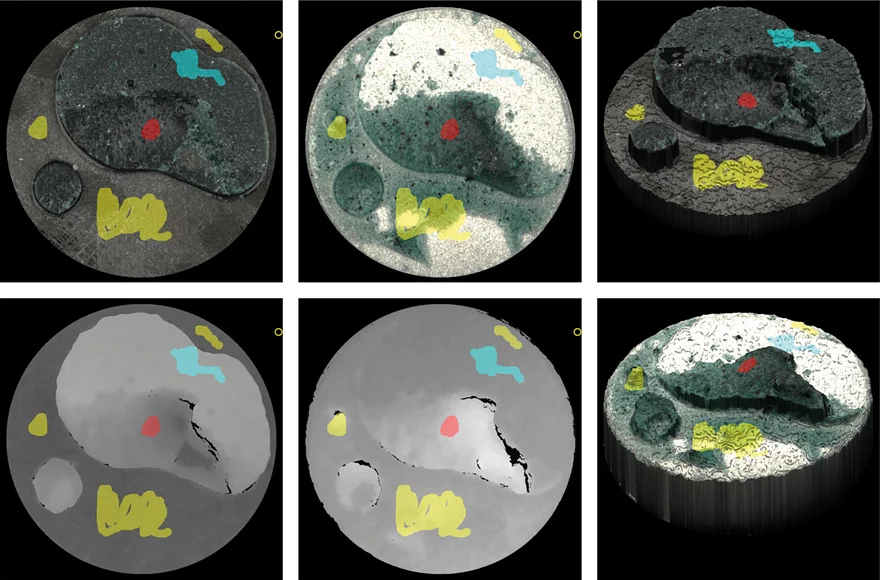

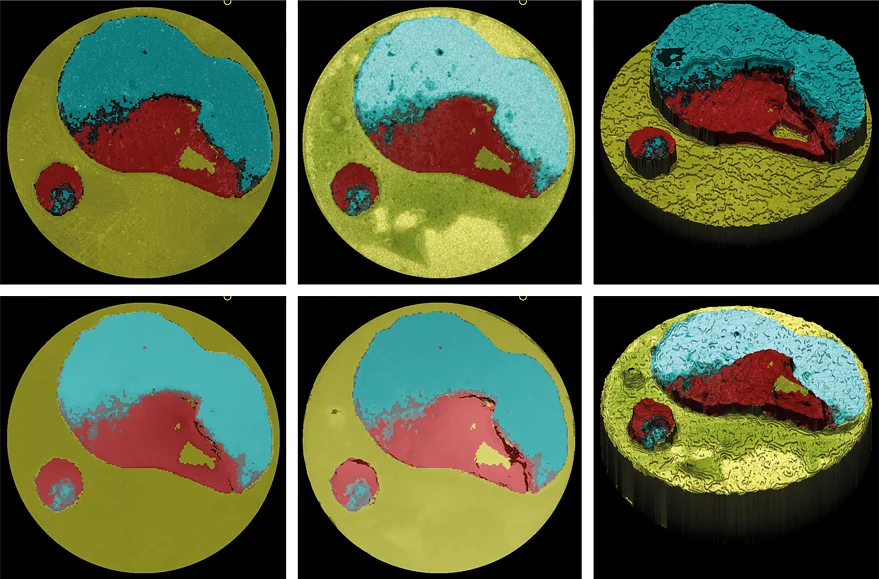

Annotation assistant: Bond Experts annotate the sample simultaneously in all 6 views, wherever a pattern is easiest to identify

Advanced algorithms: Machine-learning algorithm for quick and easy sample analysis

- High-resolution image (11 µm/pixel, 2302 dpi) of up to 8 fracture pairs

- 3D height information with 20 µm resolution

- Annotation assistant with Pair of Assignment: Labeling of the sample is performed in parallel in both the height and high-resolution images and is displayed simultaneously in the 3D image - wherever a pattern is easiest to identify

- Complete inspection in less than 2 minutes

- Semi-automatic mode and process mode. Prediction mode for dealing with very frequently changing substrate/adhesive samples

- All results are logged and all relevant data is stored in a database for easy retrieval of previous results. A pdf file is created automatically containing all relevant information